MUSCATINE, Iowa — The City of Muscatine is partnering with local education and housing organizations to build 3D-printed homes.

The groups are working with Alquist 3D, a U.S. company specializing in 3D-printing houses.

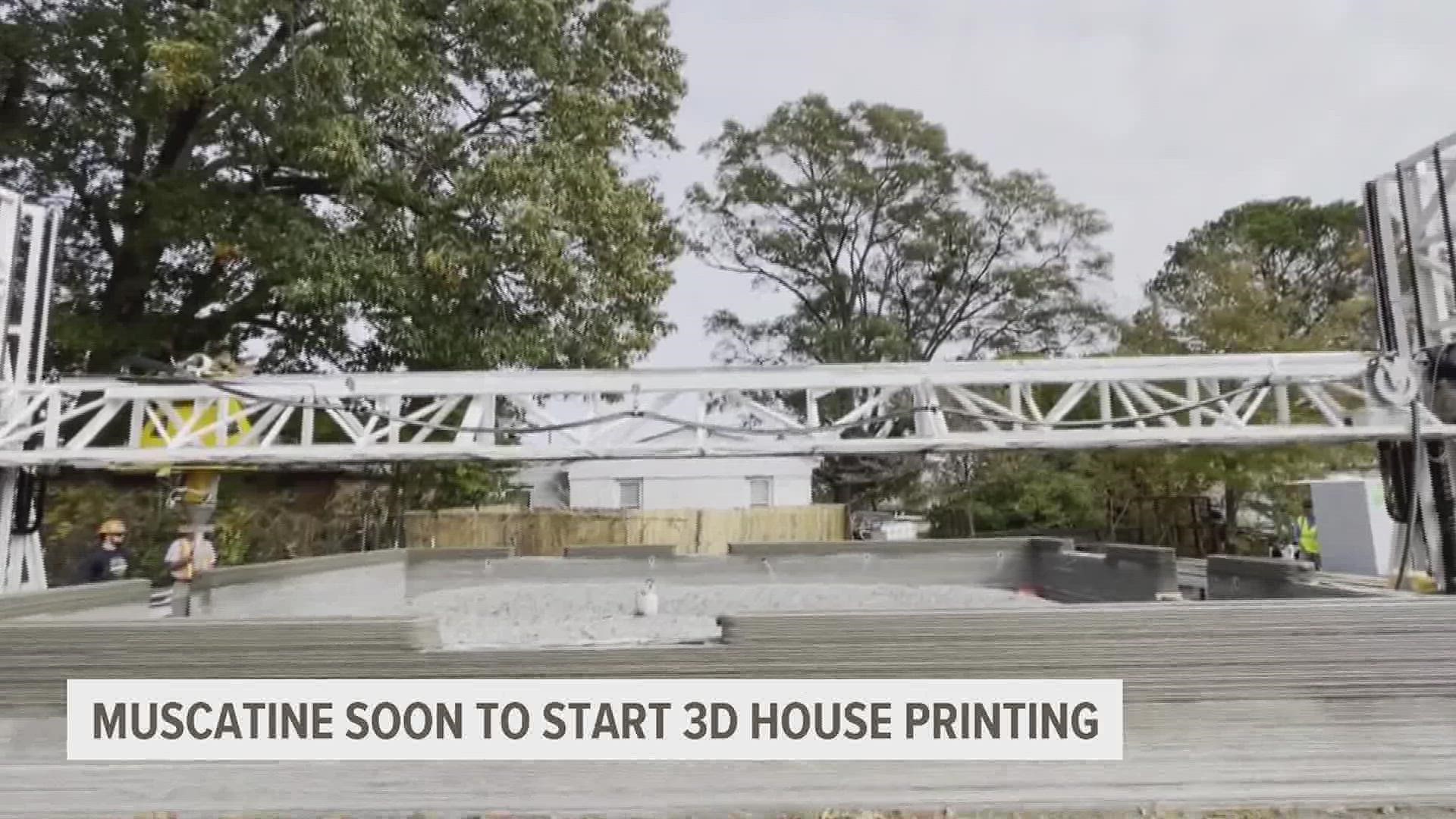

The 3D printer uses a cement-like mixture to construct the walls.

Project leaders said they chose 3D printing over traditional methods because of the need for less manpower and costs. They estimated that they save around $50,000 on each home with 3D printing.

Founder and CEO of Alquist 3D, Zachary Mannheimer, said the group is using a more cost-efficient material called hempcrete, a carbon-negative material, reducing home utility costs.

"We're working on a grant right now with Texas A&M University that's already successfully created a hempcrete," Mannheimer said. "We want to do that here in Iowa, we think that's going to reduce not just the cost of the material, it can make it stronger."

Officials are unsure how much the new homes will cost, but 3D-printed homes can cost up to a third less to build compared to regular homes.

"The average psi of the concrete that we're using today is about 75 hundred, or three times stronger than traditional concrete," Mannheimer said.

Organizers also said it's much faster, giving them extra time to build more houses.

"When you're 3D-printing a house and you can get the walls done in 24 hours, that creates a lot of time to do other things," Scott Dahlke from the Muscatine Center for Social Action said. "The interior finishes - they still they still require the time that they've always required - but we can get that exterior done quicker."

Many of the houses will be built in a neighborhood near 6th and Orange Streets, which is close to local shops and Jefferson Elementary School.

Project leaders said they chose this location to support the education community, namely teachers.

"We know that over 30% of teachers here in our community are living outside our town and commuting in," Dahlke said. "We know that they're more likely to have a longer tenure if they live in town."

The housing will also support young students and their families.

"Kids that move frequently are often set back educationally - up to six months," Dahlke said. "We know that kids in this in this district are moving three to five times per school year, so we could start stabilizing some of that with these houses that we're 3D-printing. I think that would just be tremendous."

Organizers are also working with Muscatine Community College, giving their students hands-on learning by inviting them to work on the houses.

"They are going to purchase their own 3D printer and teach 3D printing at the community college there," Dahlke said. "They'll be on the ground with the 3D printer learning how to do this so that they can maybe produce more people that have the skills to do this later on."

Project leaders are hoping to begin construction in the mid-summer of 2023, and finish building the 3D-printed houses by the end of 2023.