EAST MOLINE, Ill. — When you imagine what a John Deere factory looks like, you likely imagine a sea of green and yellow, hard workers, and a lot of equipment. You'd be right, but there's a new employee on the scene that helps make decisions to make the factory run smoothly its name: Artificial Intelligence.

According to the International Trade Administration, the AI industry was worth $66.8 billion in 2021. AI is also expected to add an estimated $15 trillion to the global economy by 2030. One field you might not expect to see the technology in a corn or soybean field. For Deere and Company, the technology starts in the factory.

At Deere Harvester in East Moline, they have an internally created program called JDAAT that is pretty smart.

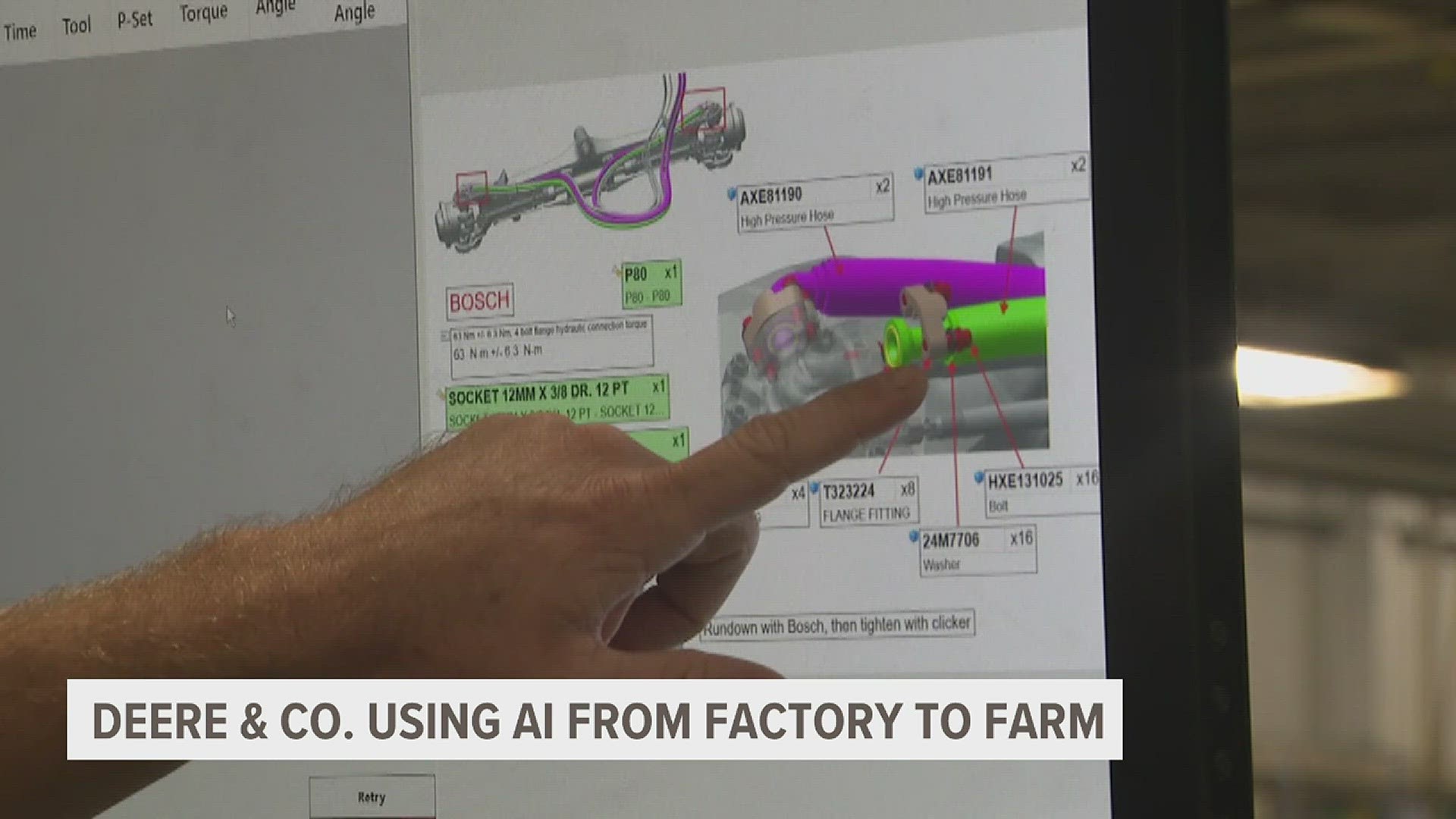

"They can't go to the next step of the process until the current step is completed," Mitch Zimmerman, Quality Engineering Supervisor for X9 combine said. A person does the work, but JDAAT checks for accuracy before a machine can go to the next step.

"Let's say 6 months from now we get a warranty claim on a machine we can try and understand what happened there," Zimmerman went on to say. It's about improving efficiency.

"If you would've been out here five years ago, you would have come up and I would've handed you a physical copy, a paper copy, of the work instructions" Zimmerman explained. Now JDAAT keeps track of all the instructions worker may need, and they change based on the project being worked on. It also knows when an employee is working in a new area and may need additional training so every product is built correctly, every time.

"It would stop me, it would make the team leader come over, we would have a conversation about all of the safety concerns in this area," Zimmerman further explained.

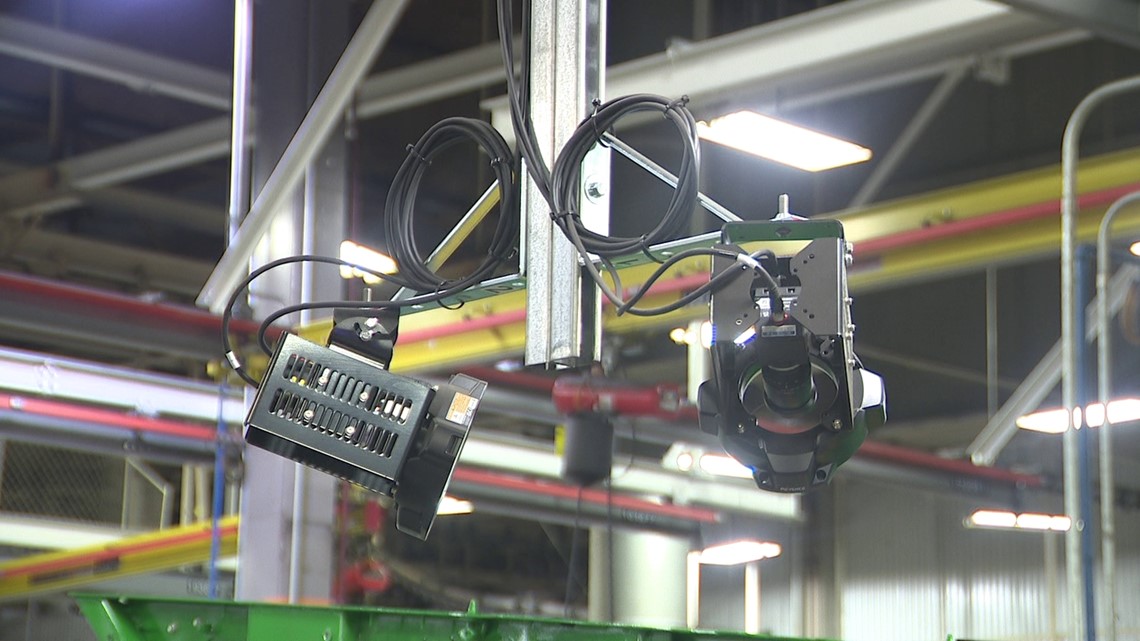

Once a job is complete, a camera, or digital inspector does final checks before it can move on.

It has incredible precision and can see if a single washer is missing on a combine, which includes around 18,000 parts on average. Even more impressive, the inspection takes less than 6 seconds.

When a human inspector did the work they had around 20 inspection points, now with the camera there are around 150.

With the advancements in technology, new jobs are created that you may not normally associate with a factory setting. "We've got data engineers, software engineers, data wranglers, data scientists," said Leigh-Ann Pendleton, Data and Software Solution Manger. "Essentially we are looking to find analytics tools that make decision-making easier, faster, optimized and really make people lives work better".

Previously, inventory would take an entire year to complete, now a robot is able to use its intelligence to track everything in the warehouse and tell employees where an item is located.

But that goal to 'make peoples lives work better' is going beyond the factory and is headed into the farmer's field.

"The combine is a factory on wheels," explained Miles Musick, Factory Engineering Manager, Deere and Company . As a farmer works the field, the X9 combine is gathering data relevant and catered to the farmer's specific field. Farmers can then take that data, make changes and continuously improve their farming practices, boosting outputs and sales. The previous "top of the line" would allow the farmer to see data field by field. New technology is allowing farmers to get technology based on individual spots in a field.

"Now it's this area of the field, this water way, maybe I need to treat it differently with my next spraying cycle for example," said Musick.

But what is a not-so tech savvy farmer suppose to do with this technology? They have trained staff that work with the farmers directly, show them how to work the equipment, create settings and how to read data. Deere and Company says the data will also have the same look and feel going from equipment to equipment.

"When the farmer gets out of the tractor pulling the planter, get into their sprayer, and then ultimately get into the combine at the end of the season, the look and feel and how they engage will be very similar," said Nathan Kramer, Product Marketing Manager for Combines and Front end.

"With the technology that's in farmer's hands right now they are able to make decisions that are almost unbelievable in some cases," Musick explained.

News 8's David Bohlman asked if the advancements of technology, and embracing artificial intelligence, will jobs be eliminated?

Musick said no. Jobs are, however being repurposed into other jobs, allowing people to leave mundane tasks behind so they can focus on critical work.

Deere and Company also has a seeding machine that uses artificial intelligence by detecting weeds in a field, and killing them with a laser so a farmer doesn't need to use harsh chemicals.

Watch more news, weather and sports on News 8's YouTube channel